sectors

Mould & Die

Safety is Key when Lifting & Handling Heavy Moulds

RUD products are well known across the mould and die sector due to the many safety features they offer. Handling of heavy plant and injection moulding tools can easily result in damages to the tools and operator if the correct equipment is not used. Safety is key.

RUD Lifting equipment and TECDOS mechanical engineering products are regularly used across the mould and die industry for standard and bespoke projects.

Lifting

The demand for mould & dies to be turned, swivelled, and twisted during the handling process is vital. For this to happen safely, the lifting equipment used needs to swivel and pivot at the same time.

RUD offer a range of lifting equipment that is regularly used across the mould and die sector.

The RUD ACP Turnado and PowerPoint Star are popular choices as they can pivot in any direction, allowing the handling of goods to run smoothly and safely.

Turn, rotate & tilt heavy moulds & tools from 1 gram to 64 tons

The RUD TECDOSTM Tool Mover enables heavy tools to be safely and effectively rotated reducing risk to your operators and damage to expensive tools. It can be used anywhere in the plant as its not anchored to the floor and is very compact. It can be moved with a hoist (lifting points) or lift truck (fork insertion points).

The RUD TECDOSTM Tool Mover is used across a range of industries from Injection moulding, automotive, tool design & construction to many more.

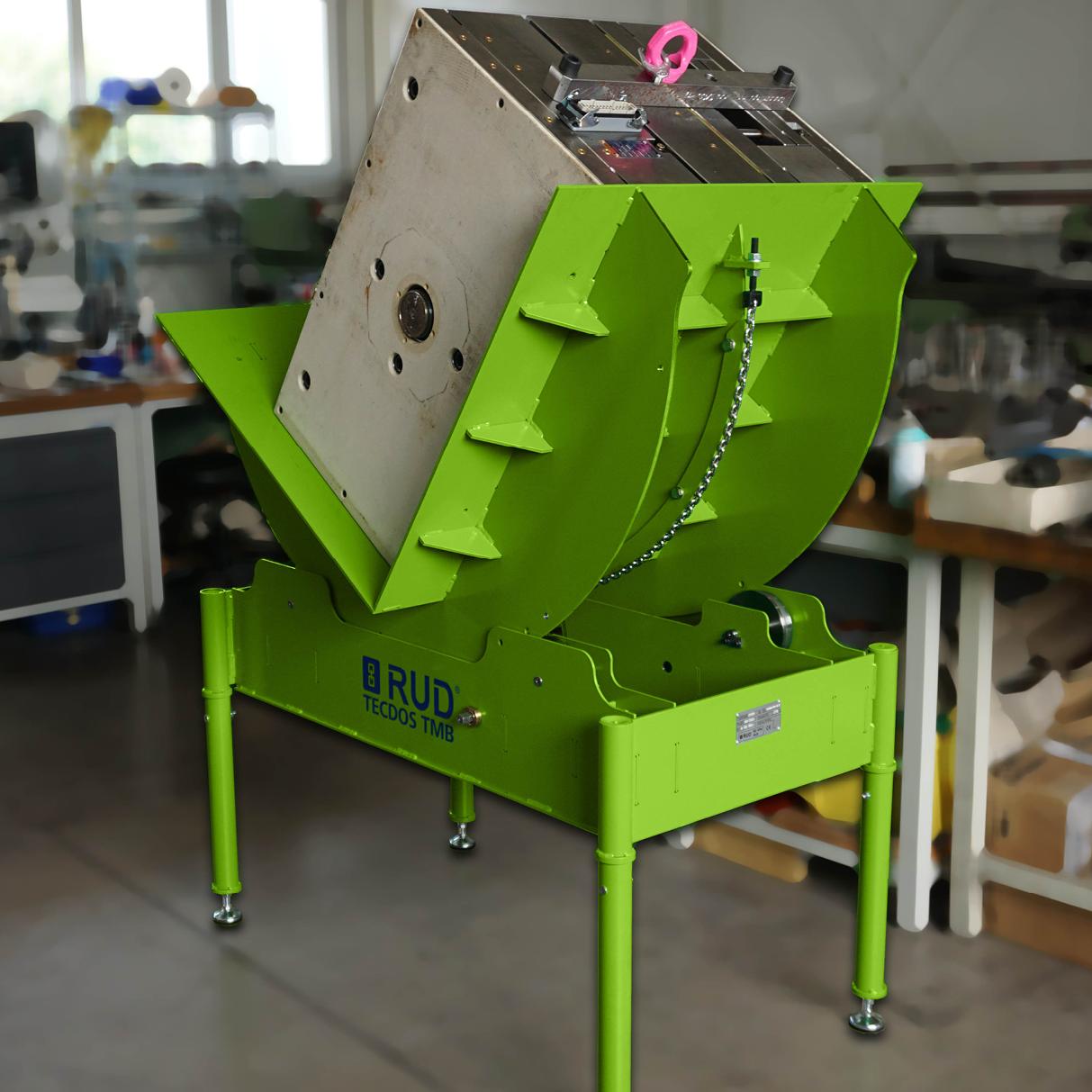

The Problem Solver for small tools, molding forms and objects

The RUD TECDOS TMB Tool-Mover Bench offers a unique combination of a workbench and a turnover device in one. It allows you to easily move, handle and maintain your tools of up to 2.5 tons with just a cordless screwdriver.

Precise & Efficient Tool-Handling

Our RUD TECDOS TS tool separator is another milestone in our Mechanical Engineering product family. With it, you can now handle massive and heavy spraying, stamping or pressing tools with ease. RUD’s in-house expertise has integrated the innovative RUD TECDOS PI-GAMMA drive system and the high-end round steel chain, ensuring efficient, cost-optimized tool management.